Coatings for Industrial Fittings

AlumiPlate’s electroplated aluminum coatings provide excellent corrosion protection for fittings and coupling used in industrial, marine and agricultural environments. The as-plated coating is fully malleable to allow crimping, swaging and forming of industrial components after plating.

Our plating can be used to lower costs by enabling carbon steel replacement of expensive stainless steel. The pure aluminum coating protects carbon steel in environments that are normally reserved for stainless steel use.

Are your products used in demanding applications, like in saltwater, marine or offshore mining operations? If the answer is “yes”, electroplated aluminum is an excellent choice for fittings, connectors, brackets and other such components.

Pure aluminum provides excellent corrosion protection against urea (a common nitrogen fertilizer), salt water, and acid rain from industrial and marine environments (sulfuric acid or nitric acid exposure). Additionally, electroplated aluminum can survive elevated temperatures significantly beyond the capability of zinc and other protective metal and organic coatings.

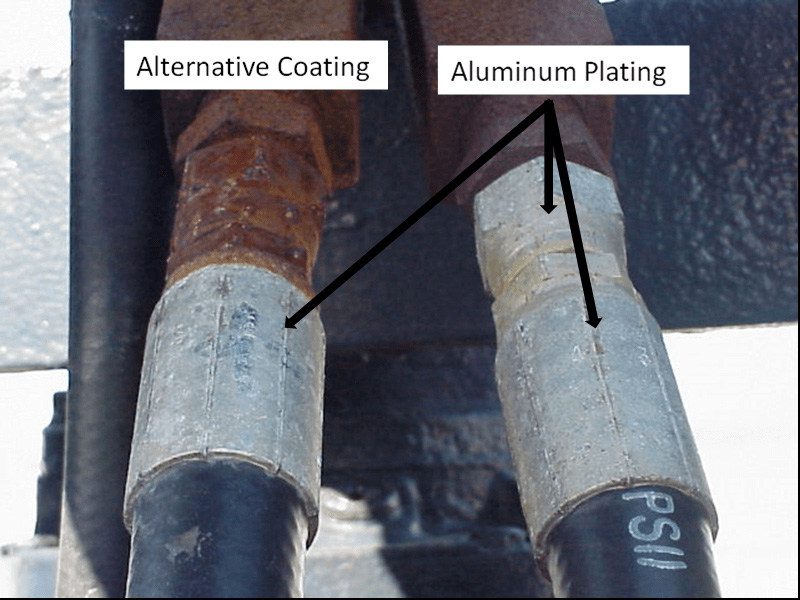

Aluminized vs Non-Aluminized Industrial Fittings

AlumiPlate’s Aluminum Coating For Industrial Use

AlumiPlate’s high purity electrodeposited aluminum coating has a long and stellar track record in helping our customers lower cost while increasing performance. Whether your application is in tube fittings for biofuel, mining applications or brackets and connectors used in a host of market applications, our surface engineering experts will help satisfy your most demanding customers.

We are experts in metal coating and have developed a process to achieve adhesion on steels and other substrates. For nearly 30 years, AlumiPlate has been solving the toughest industrial corrosion problems as a global leader in metal plating. Contact us for more information on a metal coating for rigid conduit fittings or other components, or to discuss your application in more detail.