Applications for Industrial Aluminum Plating

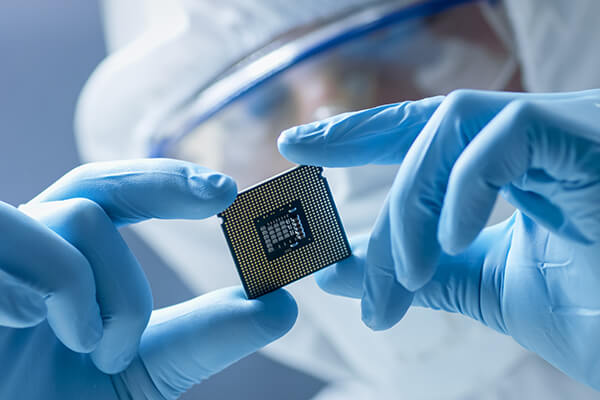

Semiconductor Fabrication

Extend life, reduce contamination & lower equipment maintenance for SemiFab etch and deposition.

Learn More

Aerospace

Environmentally friendly, outperforms cadmium, IVD aluminum and zinc-nickel, qualified for several flight-safety-critical components, surpasses MIL-DTL-83488 requirements.

Learn More

High Strength Steel

RoHS and REACH compliant, provides the highest corrosion resistance possible, eliminates hydrogen embrittlement and field re-embrittlement.

Learn More

Electronic Devices

Yields a beautiful, rugged anodize and enables novel finishes on any material (aluminum, magnesium, plastics).

Learn More

Fasteners

Provides excellent corrosion resistance and consistent torque-and-tension with a variety of available friction modifiers, meets NAS 4006 requirements.

Learn More

Electrical Connectors

High performance and able to meet 336 hours SO2 G-85 exposure, can be applied on aluminum, composites and stainless steel (SST) connectors.

Learn More

Industrial Fittings

Excellent corrosion resistance at 0.0003” thin, enables replacement of SST to mild steel fittings, ductile and highly adherent.

Learn More

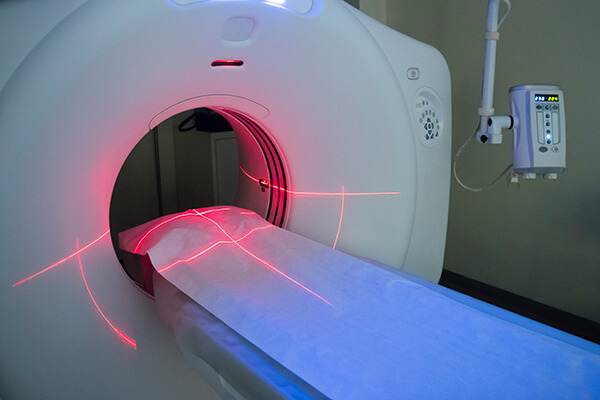

Medical/Dental Devices

Typically greater than 99.99% pure electroplated aluminum and pure alumina coatings extend the life of medical and dental devices, and are compatible with sterilization methods.

Learn More

Optics

Cryogenically stable and warp-free, typically more than 99.99% pure Al yields diamond turned surfaces as low as 10 angstroms.

Learn More

Aluminum Metallization

Typically higher than 99.99% pure aluminum metallization for quantum-computers and silicon-based devices.

Learn More