Cadmium Plating Alternative

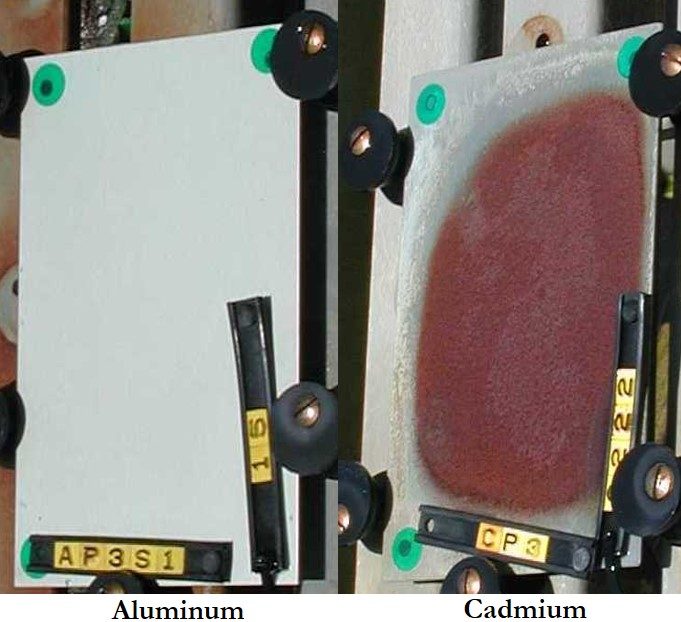

Electrodeposited Al Plating, a Replacement for Cadmium

Ample testing, going back more than 25 years, shows electrodeposited Al is the superior alternative to cadmium.

A safe alternative to cadmium plating is available. Extensive testing since 1995 by USAF, NAVAIR, ARL and others has clearly shown that the best replacement for cadmium plating is electrodeposited Al plating using the commercially available AlumiPlate® process.

Electrodeposited Al greatly exceeds the performance of Cd plate in:

- Corrosion protection

- Prevention of catastrophic corrosion-related failures

- Compatibility with the numerous Al and Mg components used in most aerospace programs and weapons platforms

Al has no identified environment, safety or occupational health (ESOH) issues, while other materials that have been considered in replacement of cadmium such as zinc/nickel (ZnNi) are now coming under regulatory pressure in Europe and the US.

Why and Where Cadmium Plating Was Used

Most weapons systems are heavily dependent on the use of steels, especially high strength steels, to provide adequate mechanical strength in a limited envelope. Unfortunately, these alloys are highly susceptible to corrosion and to catastrophic corrosion-related failures resulting from stress-corrosion cracking, environmental cracking and corrosion fatigue. Cadmium (Cd) plating has been the coating of choice since World War II to prevent corrosion. Galvanic corrosion of more electronegative alloys, such as Al, in contact with more noble materials, such as steel or titanium, is also a critical issue and, up to now, has only been controlled by Cd-plating the steel.

Cd-plating is a requirement throughout all DoD systems.

Its major uses include:

- Fasteners of all kinds in aircraft, vehicles and ships — thousands of rivets, bolts, etc. per system

- High strength steel hydraulic actuators for aircraft and vehicles (typically hundreds per aircraft)

- Electrical connector shells for all military systems (hundreds to thousands per system)

- Aircraft landing gear (fixed wing and rotary wing)

- Connectors for hydraulic and pneumatic lines

- Stainless steel sensors and actuators attached to aluminum frames.

These components are typically cadmium plated by the OEM. Any item requiring overhaul (essentially everything but fasteners and connectors) must be continually touched-up and frequently replated for corrosion control throughout the life cycle of the system at either the OEM or another authorized maintenance facility.

Why is Cadmium Plating Banned?

Cadmium is a highly toxic cumulative poison and an IARC Group 2A material (probable human carcinogen). Because it leaches easily, it is a frequent environmental contaminant from aircraft and engine washdowns. It is heavily regulated throughout the world, with a PEL of 0.1 mg/m3 in the US. Under the European rules ELV (End-of-life Vehicles), WEEE (Waste Electrical and Electronic Equipment) and RoHS (Restriction of Hazardous Substances), cadmium is restricted to no more than 0.01wt% of any vehicle and electronic material or coating, with exemptions for aircraft and military use. These exemptions are only temporary and are intended to be removed once alternatives become available. Under the new European REACH statute (Registration, Evaluation, Authorization and Restriction of Chemicals), cadmium plating is forbidden except for aircraft and some safety and electrical equipment. REACH has no exemption for military use, posing a problem for sustainment of military vehicles in Europe.

The result of this worldwide pressure is that cadmium (Cd) plating (which was once widely used in everything from automotive bolts to padlocks and deck screws) has been removed from almost all commercial use. The only remaining major uses are aircraft and military applications, and the legal exemptions for these systems are intended only to remain in force for a limited time.

There are DoD HAZMAT policy memos now being drafted and circulated regarding the elimination of restricted and banned materials on DoD weapons system programs.

Have Confidence in Your Cadmium Plating Replacement

If you want to learn more about the advantages of electrodeposited aluminum over cadmium plating, we can discuss how it will affect your specific application. Our goal is to help you make the most informed decision for your plating needs, so don’t hesitate to reach out to our friendly experts!

Contact us for more information about our alternative to cadmium or to discuss your application in more detail.