Compatible Materials For Electroplated Aluminum

Electroplated aluminum can be applied over most engineered materials to meet challenging surface finishing requirements and enhance product performance. You can apply Aluminum electroplating on steel, copper, titanium, and more to improve your products.

Contact us now to learn more or read on:

Aluminum Plating on Aluminum Alloys

Aluminum electroplating increases the corrosion resistance of all aluminum alloys and stops galvanic corrosion where titanium, steel, copper or other dissimilar metals are in contact with aluminum alloys. Additionally, pure aluminum can facilitate more uniform anodization or enable anodization of multi-phase alloys. Electroplated aluminum has been successfully applied onto wrought and cast Al alloys (1100, 2024, 5052, 6061, 7075, A-356). AlumiPlate has also developed robust plating recipes for many specialty aluminum alloys, such as Materion’s AlBeMet 162® or Osprey Sandvik’s Al/Si CE-17 alloy.

Most Materials Can Be Plated With Pure Aluminum

If you have ever wondered if it is possible to plate or coat aluminum on a specific material, the answer is most likely “Yes!”. AlumiPlate® aluminum has been applied over a wide variety of substrate materials, from the mundane (low carbon steel) to the exotic (depleted uranium).

The AlumiPlate aluminum coating is an enabling technology for materials requiring high-performance corrosion protection, high-temperature capability, electrical surface properties, and excellent cosmetic appearance.

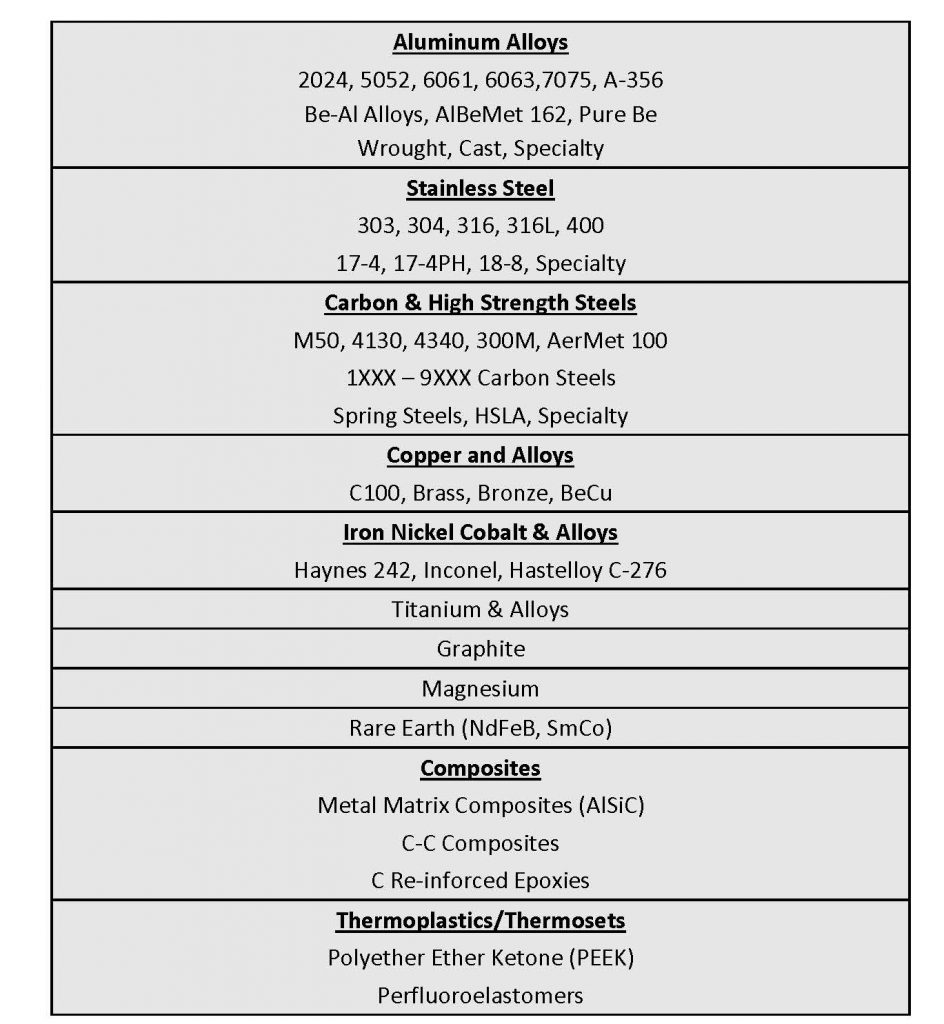

A list of materials that can be plated with aluminum is in the table below.

Aluminum Plating on High Strength Steels

The aluminum electroplating process precludes exposure to hydrogen that can lead to hydrogen embrittlement of high-strength steels. Critical components can be plated without the risk of embrittlement and subsequent requirement for a 24-hour hydrogen embrittlement “bake”. Electroplated aluminum can be applied directly on aerospace high-strength materials (M50, 4130, 4330V, 4340, 300M, AerMet 100) and high carbon steels (such as spring steels and cast irons).

See the table above or contact us if your material is not listed.

Aluminum Plating on Stainless Steels

Many applications presently using stainless steel may benefit from substituting a lower-cost carbon steel substrate with the added corrosion resistance of the pure aluminum coating. Electroplated aluminum can be coated onto SST 303, 304, 304L, 316, 17-7 PH, and Specialty stainless steels.

See the table above or contact us if your material is not listed.

Aluminum Plating on Copper, Bronze, and Brass

Copper and copper alloys are easily plated with pure aluminum. Thermal management components sensitive to corrosion from thermal fluids and the environment can be protected with electroplated aluminum. Unlike other protective coatings, pure aluminum withstands high temperatures (up to 300 °C). Electroplated aluminum can be coated onto C1100 Cu, Beryllium Copper, bronzes and brasses.

See the table above or contact us if your material is not listed.

Aluminum Plating on Graphite and Carbon Fiber Composites

Aluminum plating is an excellent choice for applications requiring the unique properties of graphite and carbon fiber composites. Graphite can be plated directly transforming the surface into pure aluminum. Carbon fiber composites can benefit from improved corrosion resistance and electrical conductivity. Electroplated aluminum can be applied on graphite (pure C), C-C composites and carbon fiber reinforced epoxies.

See the table above or contact us if your material is not listed.

Aluminum Plating on Plastics

It is possible to aluminum plate numerous plastics and polymers. Highly stable, high temperature thermoplastics and thermosets are good candidates for plating. Once compatibility with the solvent plating process is confirmed, a custom plating recipe is developed for each plastic. Typically, the surface is metalized with a copper, nickel or other conductive strikes, and then plated with aluminum. Electroplated aluminum can be plated on Polyetheretherketone (PEEK), perfluoroelastomers, Parylene, Polyaryletherketone (PAEK), Polyphenylene Sulfide (PPS), Polyvinylidene Fluoride (PVDF).

See the table above or contact us if your material is not listed.

Aluminum Plating on Ceramics and Glass

Non-conductive ceramics and glass can be coated with electroplated aluminum. The surface must be metallized with a 1 micrometer or thinner conductive strike (gold, silver, copper, iron, platinum, or carbon). The plating is then applied over the metallized layer. Ceramics, silica, alumina and glass have been successfully aluminum coated using this process.

See the table above or contact us if your material is not listed.

Aluminum Plating on Superalloys

Iron, cobalt and nickel based superalloys may require a protective coating for galvanic protection or from oxidizing environments. Applicable coatings are limited due to the high usage temperatures for superalloy applications. Pure aluminum offers a solution for temperatures up to 300 °C (or even higher if the exposure is short-term and intermittent). Tool steels, Haynes, Inconel, Hastelloy and C-276 can be protected with electroplated aluminum.

The aluminum coating can be diffused into iron and nickel alloys to form a hard, high temperature aluminide. The surface of the component gains the beneficial properties of an intermetallic (metal-ceramic) aluminide case, such as excellent wear, and resistance to oxidation and hot corrosion.

Contact us by phone call or email for a more extensive list and to discuss your specific substrate. If your material is not listed above, please contact us to confirm if a plating recipe is available or how we can develop one for your application.